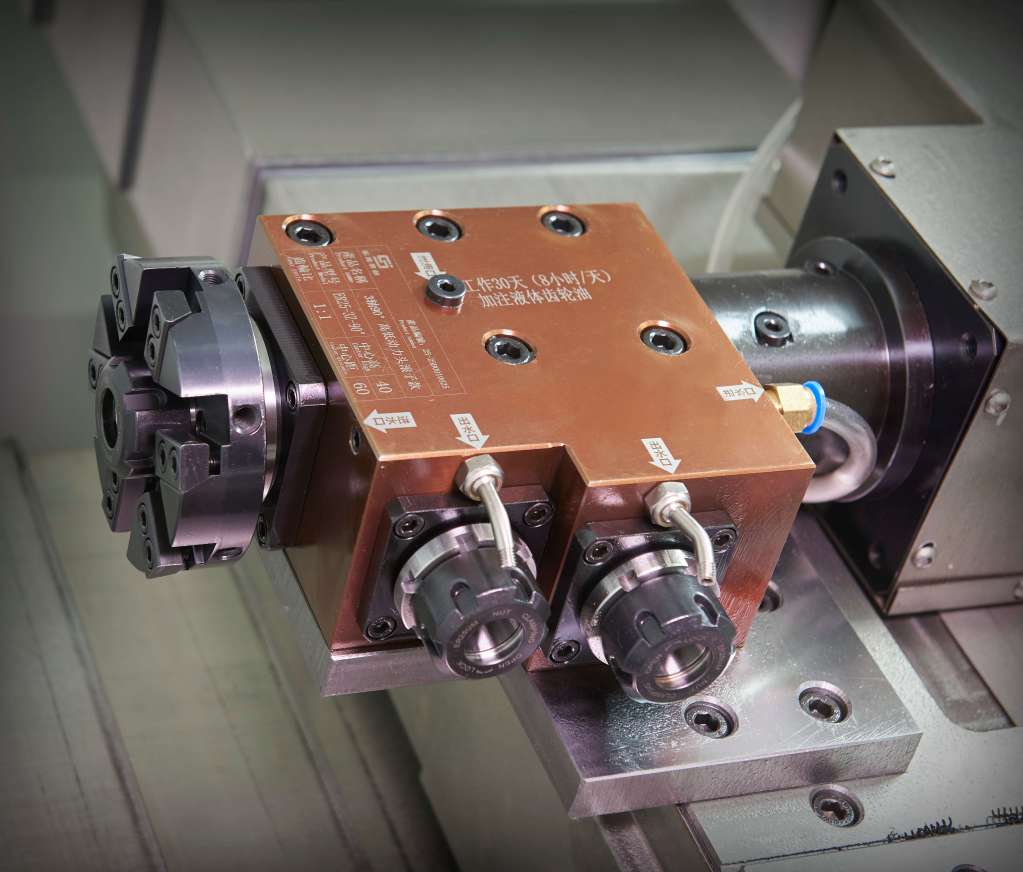

KX-46J Y-AXIS (4+4 Tools)

> Bar Materials : up to φ 45mm

> Max swing diameter: φ520mm

> X-axis travel: 1000mm

> Z-axis travel: 400mm

Engineered for robust and high-capacity machining in demanding industrial applications.

Bar Materials: up to φ64mm

Max swing diameter: φ520mm

X-axis travel: 1000mm

Z-axis travel: 400mm

| Technical Parameters | Standard Value | Maximum Value |

|---|---|---|

| Processing Capability | ||

| Spindle bore | φ64 mm | – |

| Maximum particle diameter | 200 mm | |

| Maximum length of workpiece to be processed | 350 mm | |

| Accuracy | ±0.0075 mm | – |

| Height of tool carrier center | 50 mm | |

| Maximum rotation diameter | φ380 mm | – |

| Tool holder specification / Tool capacity | 8/16 | |

| Travel | ||

| X axis travel | 1000 mm | – |

| Z axis travel | 400 mm | – |

| Feed | ||

| X-axis fast movement speed | 18m/min | 25m/min |

| Z-axis fast movement speed | 18m/min | 25m/min |

| X axis servo power | 1.5kW | – |

| Z axis servo power | 1.5kW | – |

| Spindle | ||

| Spindle speed | 3000 rpm | |

| Spindle motor power | 5.5 kW | 7.5 kW |

| Spindle nose | A2-5 | – |

| Size of applicable hydraulic chucks | 8 inch | |

| Dimensional & Weight | ||

| Dimensions | 2120 x 1620 x 1700 mm | |

| Weight | 2900KG | |

| Specification | Standard | Optional |

|---|---|---|

| CNC Control System | YASHU/NANJINGKT | SYNTEC/GSK/LNC |

| Screw | 32 mm C3-grade ball screw | – |

| Guide rail | 30 mm P-grade linear guide | – |

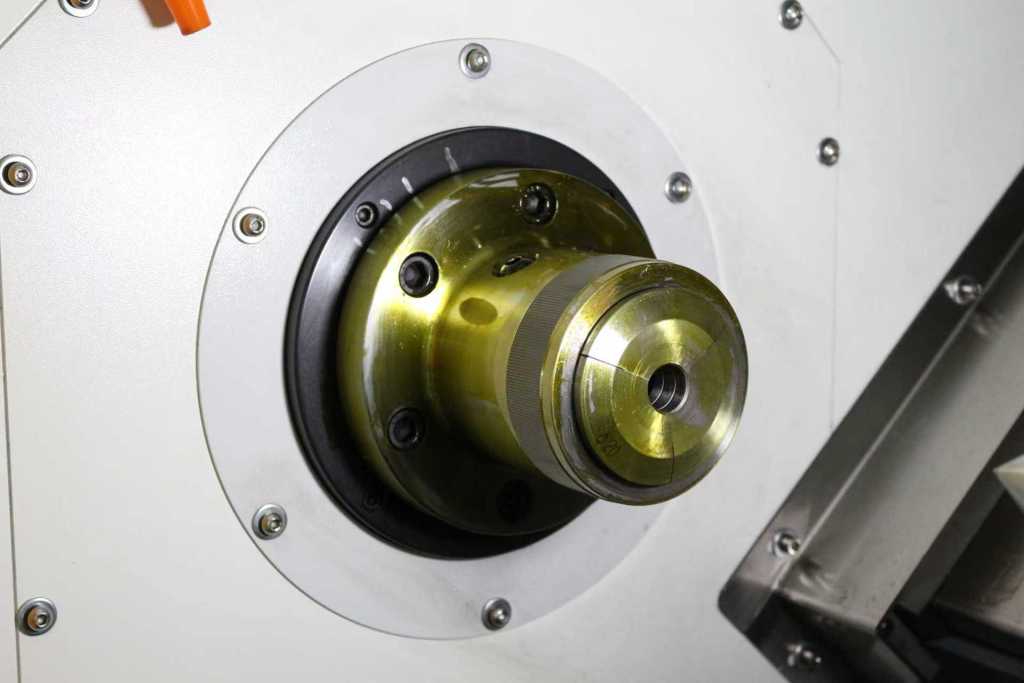

| Spindle | YASHU High rigidity barrel spindle | |

| Total Power | 9 Kw | |

| Feed servo motor | 1.5 kW servo motor | – |

| Tpye of bed | 35° Slant bed | – |

| Base Structure | Patented anti-deformation base | – |

| Clamping | Hydraulic clamping | – |

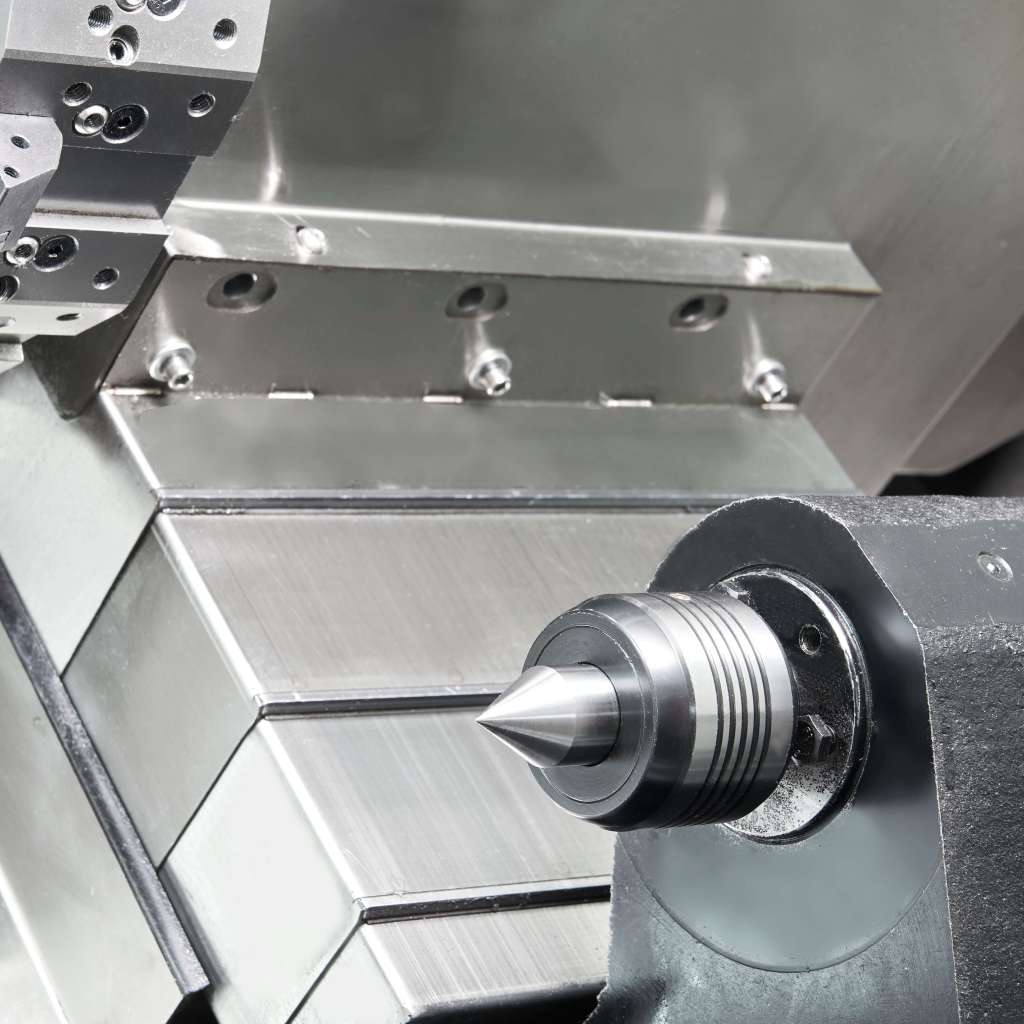

The use of heavy-duty super casting structural base ensures sufficient weight while also providing anti-deformation and vibration absorption, thereby maximizing accuracy, smoothness, and rigidity. Suitable for processing products with a length of 500 mm and a diameter of 400 mm or less that require tailstock machining using a chuck, and can be equipped with a power turret for turning and milling processing.